Commercial Applications

ultrashort pulse applications

applications

Agility & Scalability

Ultrashort pulse lasers are ideal tools for processing a multitude of materials and have been the fastest growing market segment in recent years. These USP sources provide a technique known as cold processing of the material, meaning that there is essentially no heat input on the workpiece.

Manufacturing

NexGen Manufacturing

Lasers have been applied across a broad range of manufacturing applications including marking, surface texturing, cutting, ablation, welding, and drilling. Various materials and processes require different wavelengths, waveforms, pulse energies, and repetition rates for optimized performance. New USP laser technologies being developed by Applied Energetics permit maximum flexibility across the critical operating parameters allowing for advanced and emerging manufacturing processes and throughput to be realized.

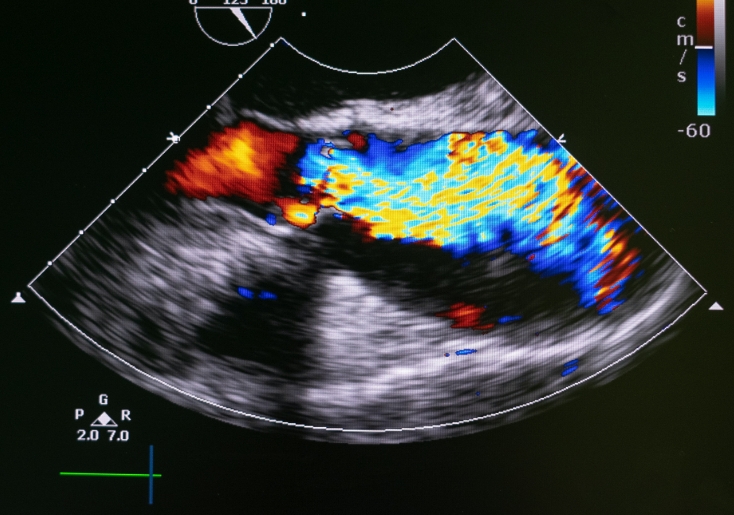

Biomedical

Detection & Imaging

Medical applications for lasers inherently rely on light interacting with biological materials. Their molecular constituents’ response to high intensity light can be exploited to allow for a broad range of applications including chemical analysis, pathogen detection and neutralization, ablation, cauterizing and imaging of biological processes taking place over long periods of time from the cell level to the full anatomy. High intensity short pulse duration lasers that are tunable in wavelength are especially useful since they can be tuned to the natural molecular frequencies of the constituents within the biological tissues allowing for highly selective processes and analysis to be exploited. At the forefront of the field, scientists can utilize wavelength-agile USP lasers for imaging living, intact organisms beyond the diffraction barrier using fluorescent proteins. Such super-resolution techniques not only allow non-invasive investigation of the interior of biological cells, but also show future promise for the nano-imaging of semiconductor devices in the electronics industry.

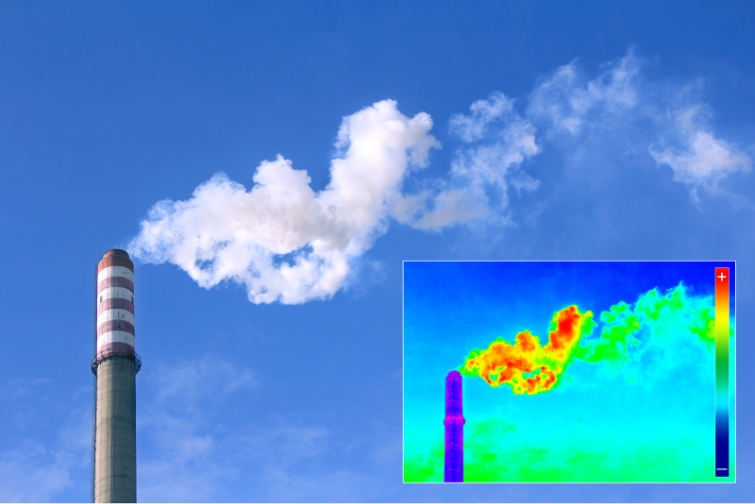

Spectral Sensing

Molecular Interrogation

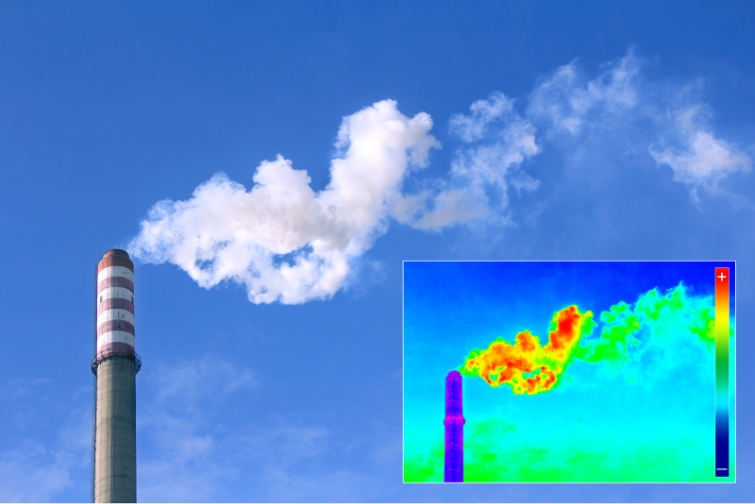

Infrared spectroscopy is an important technique for measuring the underlying composition of molecules. By measuring the interaction of light with the vibrational states of a molecule, the types of atoms, their chemical bonds, and energy states can be inferred. These measurements can be in the form of absorption or emissions as the light interrogates a molecule and leads to what is referred to as a “molecular fingerprint”. The ability to tune wavelengths over a broad spectral range allows for certain aspects of the molecular fingerprint to be determined from an absorption spectrum. A tunable high peak intensity laser drives the molecule to emit light at shifted wavelengths which are unique to the molecular bonds. Together these measurements allow for a more complete picture of the molecule to be determined in a non-destructive manner. These USP system applications can include stand-off detection and mapping of green house gases such as CO2 and methane, both of which are critical to understanding climate change influences better.

Why short pulse

Benefits of Short Pulse

Ultrashort pulse lasers have a very broad range of applications across multiple commercial markets including the medical, material processing, and remote sensing markets. Ultrashort pulse lasers concentrate the output energy into a very short duration, typically in the few picosecond to 100 femtosecond regime, and deliver extremely high optical intensities in the gigawatt to terawatt range. The resultant high peak intensity laser-material interaction provides several key advantages including complete ionization of the material by nonlinear processes with minimal thermal effects. This results in high quality processing of nearly any material thereby allowing for previously difficult or impossible manufacturing methods to be realized.